D3T4H2S

A data-driven digital twin for improved hydrogen storage vessels towards challenges for the energy transition

The project will be implemented across multiple countries, including France, Romania, Morocco, and South Africa.

S VERTICAL, an engineering company specialized on the development of software and methodologies for design, optimization, and manufacturing of composite overwrapped pressure vessels (COPV).

The overall objectives of the project can be summarized as follows:

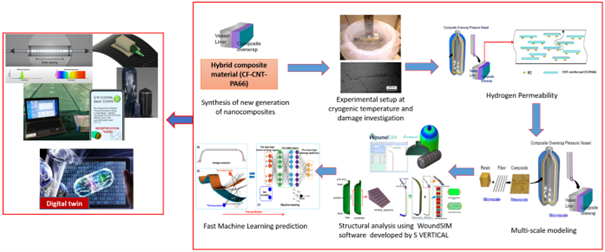

By achieving these objectives, the project aims to advance the field of hydrogen storage technology by developing innovative composite materials, improving the understanding of composite behavior at cryogenic temperatures, and providing advanced tools for efficient and cost-effective life-cycle management (Fig. 1).

In recent years, the urgency to develop alternative energy technologies has intensified as governments around the world strive to address the profound environmental and economic challenges posed by CO2 emissions. The adverse effects of climate change, resource depletion, and air pollution have propelled the search for sustainable and clean energy solutions. In this endeavour, hydrogen has emerged as a promising candidate for replacing fossil fuels, particularly in the transportation sector. However, the successful implementation of hydrogen as a renewable energy alternative is largely dependent on two critical factors: safe storage and efficient transportation. Without robust and reliable methods to store and transport hydrogen, its potential remains largely untapped. This is where our project comes into play.

Our aim is to address the pressing need for advanced technologies and scientific breakthroughs in the field of hydrogen storage and transportation. By focusing on the development of a hybrid carbon fiber-reinforced polyamide 12 composite doped with carbon nanotubes, we are striving to create ultralight cryogenic composite vessels (ULCCVs) that ensure the secure storage and reliable transportation of hydrogen. The significance of this project lies in its potential to revolutionize the renewable energy landscape. By enabling the safe and efficient storage and transportation of hydrogen, we are paving the way for its widespread adoption as a sustainable energy source. This, in turn, contributes to the achievement of the 2030 Agenda for Sustainable Development, specifically the goals related to affordable and clean energy.

Furthermore, our research addresses the limitations of the existing literature, as the development of a predictive tool using a doubly reinforced composite made of CF-reinforced PA12 doped with CNT for the design of optimized hydrogen storage tanks has not been previously explored. This project will bridge the gap between material sciences and structural design, utilizing advanced in-situ characterization techniques and micromechanics to enhance our understanding of the composite’s behavior. By developing an expert tool for the management and predictive maintenance of ULCCVs, we enable real-time monitoring, accurate prediction, and timely correction of potential problems. This not only reduces costs but also ensures optimal operation, thereby maintaining a competitive advantage for hydrogen applications.

The project encompasses a series of concrete actions to achieve its objectives. It begins with the careful selection of suitable batch materials, considering their properties and compatibility with the project goals. Next, the manufacturing process focuses on producing thermoplastic composite materials with precise composition and controlled fiber alignment and nanotube dispersion. These materials undergo meticulous microscopic and macroscopic analysis and testing, enabling a comprehensive understanding of their internal structure and mechanical, thermal, and chemical properties under cryogenic conditions. Through evaluation and selection, the project identified the most promising composite materials that exhibit improved structural integrity, microcrack resistance, and suitability for cryogenic temperatures. Thermo-mechanical properties are extracted and utilized for analytical and finite element analysis, allowing accurate predictions of the composite’s behavior in different scenarios. A key aspect of the project is the development of a data-driven digital twin, which integrates physical data and employs advanced modeling techniques. This digital twin acts as a virtual replica of the composite vessels, enabling real-time monitoring, predictive maintenance, and optimization of hydrogen storage. The deployment of the digital twin contributes to the improved reliability and safety of hydrogen storage and transport.

The project results and findings are widely distributed through academic publications, conferences, and knowledge sharing activities. Collaboration with national and international networks strengthens knowledge exchange and contributes to emerging topics in hydrogen technologies, polymers, composites, and digitalization efforts initiated by the European Union.

By executing these concrete actions, the project advances the development of hybrid carbon fiber-reinforced polyamide 12 composites doped with carbon nanotubes for ultralight cryogenic composite vessels. It also pioneers the usage of a data-driven digital twin, bridging the gap between material sciences and structural design. Ultimately, these efforts support the EU’s hydrogen strategy, facilitate the decarbonization agenda, and contribute to the broader advancement of renewable energy technologies.

The expected impact of the project is multi-faceted, addressing key aspects of the AU-EU Research and Innovation Partnership on Climate Change and Sustainable Energy (CCSE) policy. By focusing on hydrogen storage, composites, artificial intelligence, and digitalization, the project strengthens national knowledge networks and contributes to advancing emerging topics initiated by the European Union.

One of the significant impacts lies in the enhancement of knowledge networks related to hydrogen storage. The project will deepen our understanding of the complex interplay between materials, structural design, and storage technologies. By leveraging the expertise of academic and industrial partners, the project fosters collaboration, knowledge sharing, and capacity building, contributing to the development of a skilled workforce in the field of hydrogen technologies. Furthermore, the emphasis on composites and artificial intelligence is instrumental in driving innovation and technological advancements. Through extensive research and experimentation, the project aims to develop advanced composite materials with improved mechanical properties, structural integrity, and resistance to harsh environmental conditions. The integration of artificial intelligence and simulation tools enables more efficient and accurate prediction of material behavior, facilitating the design and optimization of hydrogen storage vessels.

An important aspect of the expected impact is the advancement of emerging topics related to digitalization and the integration of physical data in hybrid twins. By developing and deploying a data-driven digital twin, the project enables real-time monitoring, predictive maintenance, and optimization of hydrogen storage vessels. This technological advancement not only enhances the reliability and safety of hydrogen storage but also contributes to the broader digitalization efforts initiated by the European Union. Moreover, the project’s focus on ensuring the suitability of simulation tools for future industrialization demonstrates a commitment to practical applicability and scalability. By aligning with evolving technological developments, the project ensures that the simulation tools developed are ready to be integrated into industrial processes and support the broader industrialization of hydrogen storage technologies.

By continuing to use the site, you agree to the use of cookies. more information

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.